- #Aluminum silkscreen frames Activator

- #Aluminum silkscreen frames registration

- #Aluminum silkscreen frames free

To us quality and consistency are paramount.

Orders to UK mainland are usually fulfilled within 24 hours direct from our manufacturing facility in Croydon, South London.

#Aluminum silkscreen frames registration

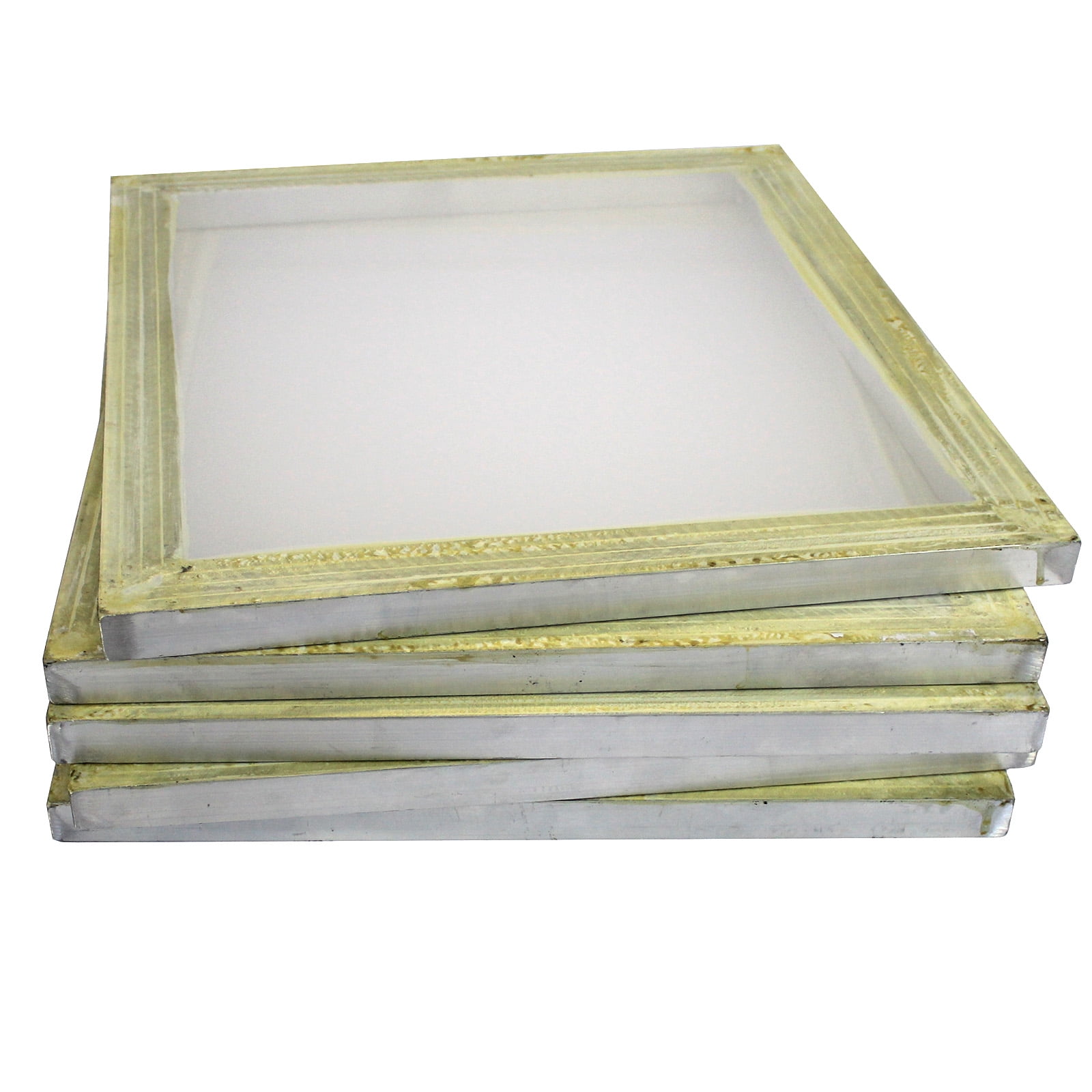

Our products are supplied to customers who print using presses from all the major manufactures including: Atma, M&R, Sakurai, Sias, SPS, Svecia & Thieme. We also offer a range of handles, coating troughs and custom built stretching tables. We fit inserts, registration bars and custom fixings on demand. We have manufactured precision screen printing frames since 1978 and continue to develop our products in order to meet the most demanding specifications. We offer a range of over 50 frame sections which we can guarantee will exceed the needs of all screen printers. All Angell Frames are made from special, high-tensile ali, being at least 40% stronger than standard aluminium. The adhesive cures to a handling strength in seconds so it is possible to put the silkscreen into service soon after bonding.Ĭyanoacrylates offer good chemical resistance to printing inks and form a strong bond between the frame and mesh to withstand the high tensile / slight peel force that is exerted on the mesh when a squeegee runs across it.įor further help with silk screen mesh bonding applications, please contact Permabond.Angell Frames are the UK’s No1 Screen Printing Frame Manufacturer.

#Aluminum silkscreen frames Activator

The surface can now be sprayed with cyanoacrylate activator to speed up cure and prevent any surface tackiness. Do not use a knife to cut the tape or you could end up damaging the mesh – instead, use the edge of a credit card.Īpply the adhesive around the edge, it should wick through the weave of the mesh and bond the mesh to the silkscreen frame. If necessary, use masking tape around the inner edge to keep a clean straight bonding area which does not encroach into the printing area. Stretch mesh across frame and weigh it down or clamp it.

#Aluminum silkscreen frames free

Make sure the surface is dry and dust free before bonding. Wooden frames should also be cleaned and any old cured adhesive sanded off. Mesh bonding should be done as soon as possible after surface preparation, otherwise a weak (and invisible) oxide layer will start to form again, resulting in a much lower strength bond. Once the surface has been roughened, it is essential to repeat the degreasing process. Two methods that will provide an excellent surface ready for bonding are abrading with 320 grade (approximate) carborundum grit paper or, if you have the luxury in your workplace, using a gritblaster. If using an aluminium frame it is a good idea to degrease with acetone or isopropanol and abrade the surface. It is important to ensure the frame is clean and free of any previous adhesive remnants. It is a juggle to get the adhesive properties right – which is why using an activator after applying the adhesive can help even up the balance, allowing an adhesive viscosity that will have ample penetration into the silkscreen mesh but stopping the adhesive flow (potentially away from the bond area) and providing a tack-free cure by spraying with the activator. You need an adhesive that will penetrate the mesh but at the same time not flow uncontrollably. Silk screen mesh is normally made of woven material such as polyester and the density of the weave dictates the viscosity adhesive you require. The process is simple and will have a screen print frame up and running again in a relatively short time compared with some other mesh bonding adhesives. Silk screen mesh bonding can be carried out quickly and effectively with cyanoacrylate adhesive and if necessary, a cyanoacrylate activator.

0 kommentar(er)

0 kommentar(er)